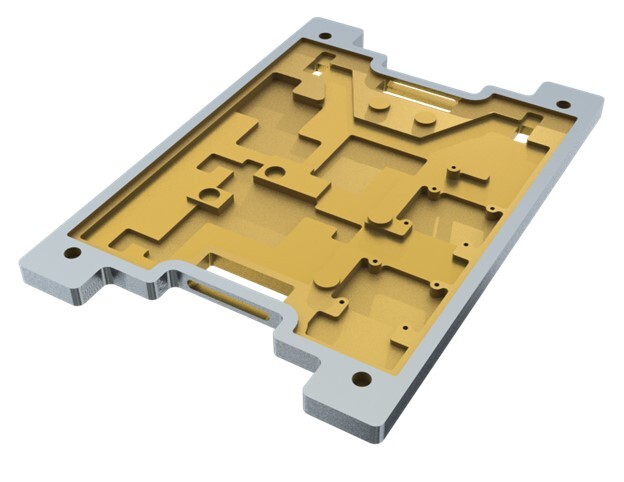

RF Machined Housing

Precision Engineering for High-Frequency Applications

RF (Radio Frequency) machined housings are crafted using precision machining processes to meet specific requirements for shielding, durability, and performance in high-frequency applications. These housings play a crucial role in industries such as telecommunications, aerospace, military, and electronics.

Material SelectionRF housings are typically made from metals with excellent electrical conductivity and shielding properties, such as:

The material choice ensures effective electromagnetic interference (EMI) shielding, essential for RF applications.

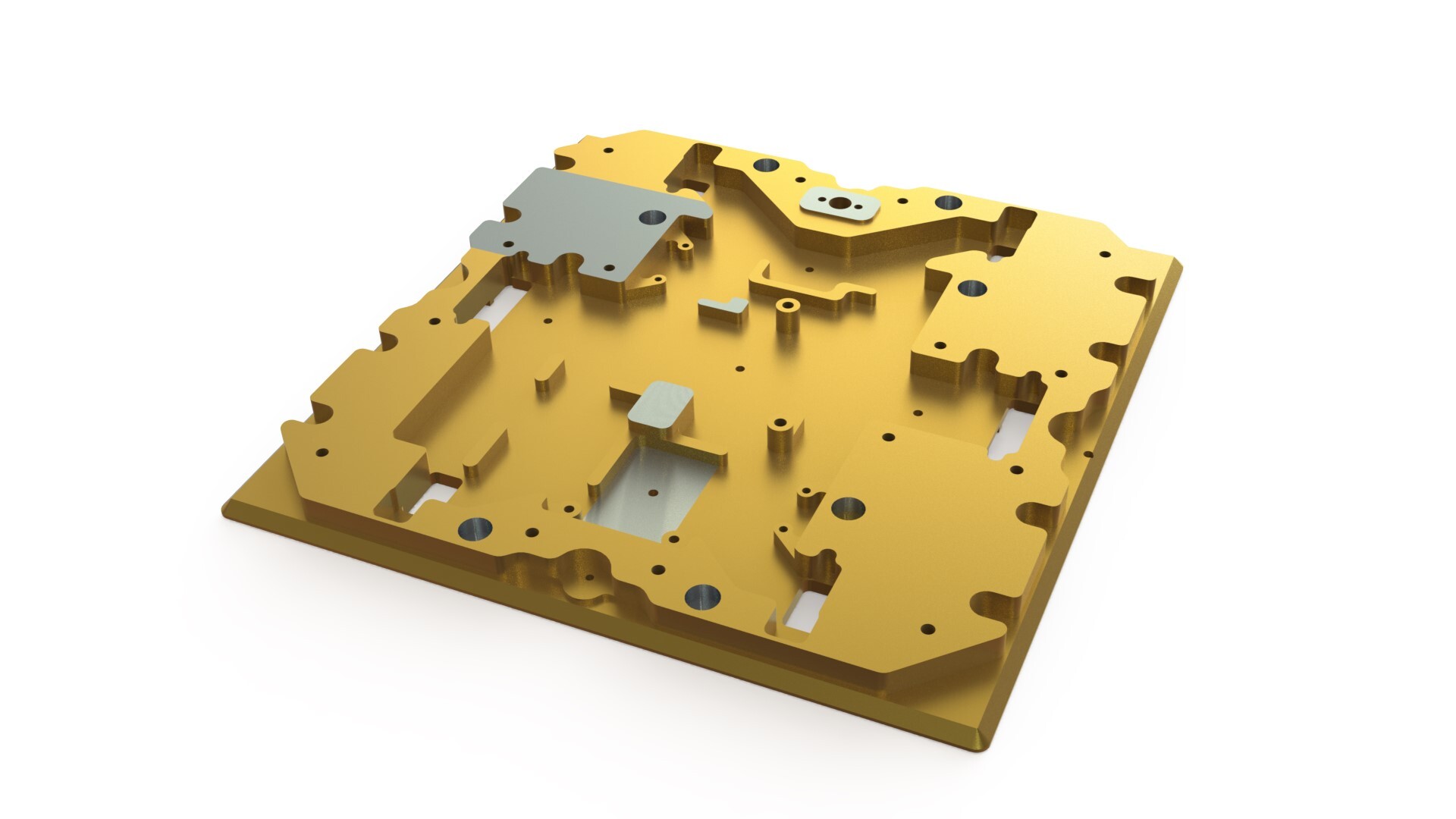

Design Process

The process begins with a detailed computer-aided design (CAD) model that defines the exact dimensions and features of the housing. This design incorporates RF-specific features, including:

Special attention is given to RF performance, ensuring a uniform, low-resistance conductive surface.

Manufacturing Process

After finalizing the CAD model, manufacturing begins with CNC machining to mill and turn the material into the desired housing shape. Key steps include:

Applications

RF machined housings are vital for devices requiring high-frequency signal management and EMI shielding. Industries that rely on these housings include: